Capacities

A variety of process machines to meet different manufacturing needs

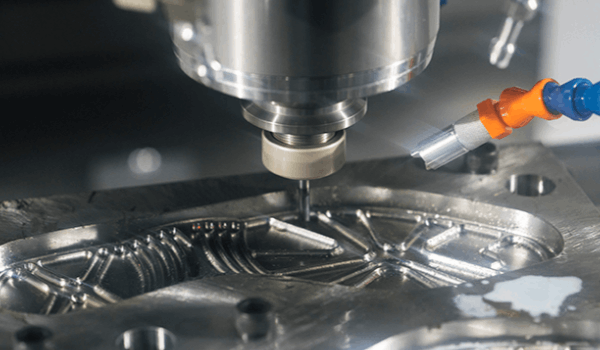

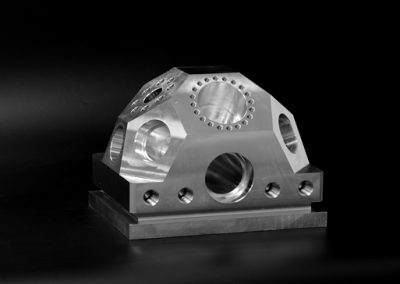

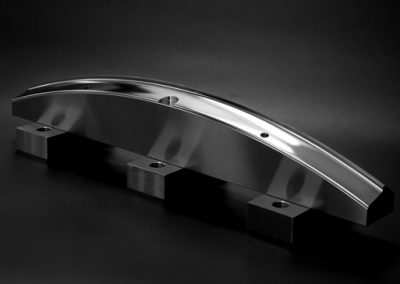

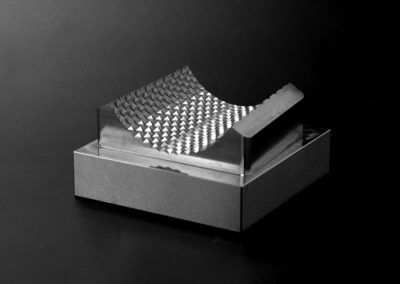

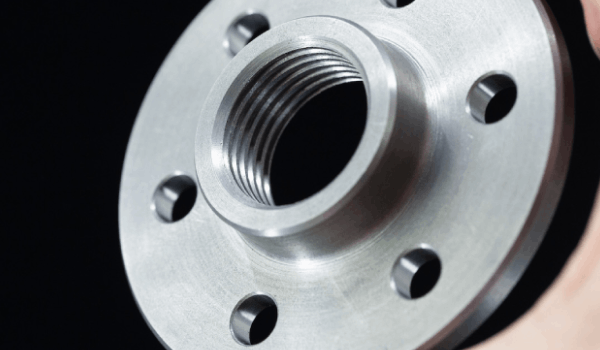

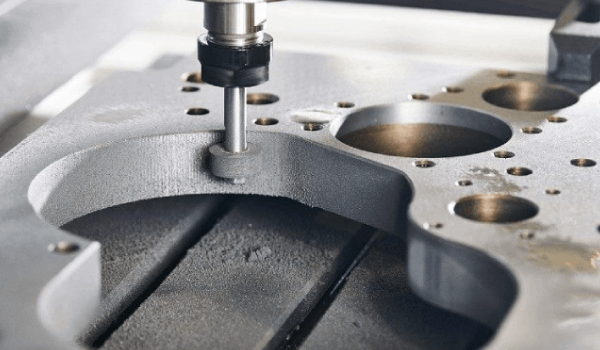

5-axis CNC Machining Service

Besides sheet metal, we also provide 5 axis CNC machining service. This extra machining service can ensure our customer to get a complete manufactured product from our ends. We use advanced 5 axis machines to meet complex or simple geometric mechanism workpiece.

Simply speaking, you just need to upload the 3D design file, then you will get the one-stop solution, including milling and turning metal parts, sheet metal for automotive or medical housing and assembly to be a whole part.

CNC Parts Made by 5 Axis

Multiple Options for Sheet Metal

MY sheet metal has an extensive line of sheet metal machinery for virtually every aspect of sheet metal working. Our advanced cutting and motion control technology provides high-speed cutting and unrivaled precision to maximize your productivity and profit margins. The advanced machines provide industrial cutting with quick installation modular design.

We also have different types of bending machining to shape custom sheet metal for your product. The thickness up to 20mm and cutting area up to 4000mm. We provide several sheet metal manufacturing processes for your customer design and requests.

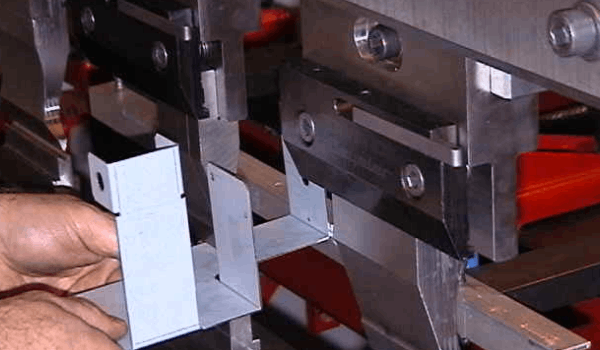

Bending

CNC bending (or) CNC forming is the process whereby sheet metal is re-shaped from a flat form. Using CNC bending, one can produce almost any component design. A basic example of this would be the creation of a 90-degree bend transforming a flat piece of metal into an ‘L’ shaped bracket. CNC bending (or) CNC forming is the process whereby sheet metal is re-shaped from a flat form.

Curling

Curling is a sheet metal forming process used to form the edges into a hollow ring. Curling can eliminate sharp edges and increase the moment of inertia near the curled end. Other parts are curled to perform their primary function such as door hinges.

Ironing

Continuous cast-iron offers many advantages over sand cast iron and other metals, like steel and aluminium. Its fine-grained microstructure performs like a built-in chip breaker and is significantly more uniform than what is possible with many other metal casting methods.

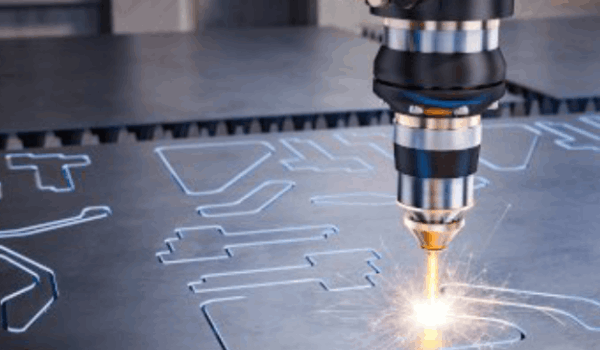

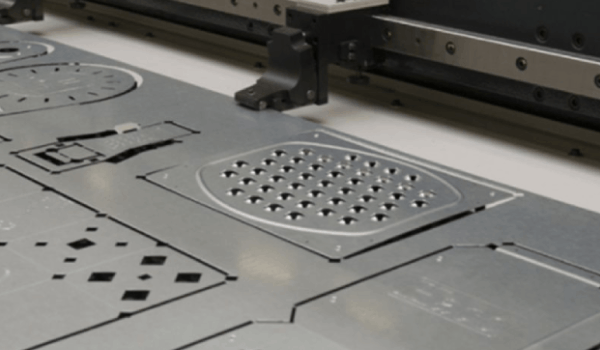

Laser Cutting

Laser cutting is mainly a thermal process in which a focused laser beam melts material in a localised area. A co-axial gas jet, is used to eject the molten material and create a kerf. A continuous cut is formed by moving the laser beam or workpiece under CNC control.

Hydroforming

Hydroforming (Sheet Hydroforming) is a specialised deep draw process that uses high-pressure rubber to shape and form metal workpieces. In sheet hydroforming, a metal sheet is kept over a die before highly pressurised water forces it down and makes it conform to the shape of the mold.

Punching

The CNC punching programme moves the sheet metal in an ‘X’ (left and right) and ‘Y’ direction (in and out), such that it is precisely positioned under the machine’s punching ram. This then forces down the tooling to ‘punch’ an accurate hole or shape into the material clamped firmly in place.

Finishing

MY sheet metal provides a wide variety of finishing options that alter the surface of sheet metal fabricated parts and products to improve their corrosion resistance, enhance cosmetic appearance, and decrease cleaning time.

- Anodizing

- Bead Blasting

- Powder coating

- Electroplating

- Polishing

- Brushing

If you need more custom finishing, you can tell us the special request when you upload the designed files.

MES Plus Quality

MY sheet metal has a unique MES(Manufacturing Execution System). It’s a one-stop solution that helps in resource allocation and status, operations/detailed scheduling, dispatching production units, document control, data collection and acquisition, labor management, quality management, process management, maintenance management, product tracking, and genealogy, performance analysis. MES helps increase our efficiency and stay one step ahead of the league compared to other sheet metal fabricators. Advanced system ensures MY can provide high quality services and parts for our customers.