Medical Metal Parts

We understand special medical needs. Make the metal medical device by sheet metal process.

Medical Sheet Metal Services

Medical device manufacturing carries a considerable degree of liability and regulatory oversight. When the needs and laws change, the medical industry frequently needs to innovate and introduce new products. There is a diverse range of medical devices and usage scenarios. Materials in medical devices get periodically checked for performance and expense.

MY sheet metal has many years of experience in medical devices and related components. We give your medical equipment the robust edge they deserve. Our precision is unmatched in crafting your medical equipment to perfection. Our experts are pioneers in making long-standing, high-efficiency medical equipment.

Benefits of Using Sheet Metal in Medical Industry

Sheet metal has 2 main benefits for medical equipment. One is Seamlessness. In the medical environment, the fewer gaps there are, the more avoiding the risk of bacteria hiding. The other one is flexible. Metal doesn’t require mold changes, and embosses and knockouts can be achieved with adjustments to steps in the process without having to switch out parts. It saves your time to wait for manufacturing, especially when medical supplies are scarce.

Sheet metal fabrication is fundamental to successful developments in medical technology. Metal is durable and robust, which lends itself to easier manufacturing processes. Moreover, metal interacts with cellular processes, which results in successful medical outcomes. While other materials can perform similar functions and produce prototypes within short periods, metal is excellent for long-term use.

Sheet Metal Used in Medical Products

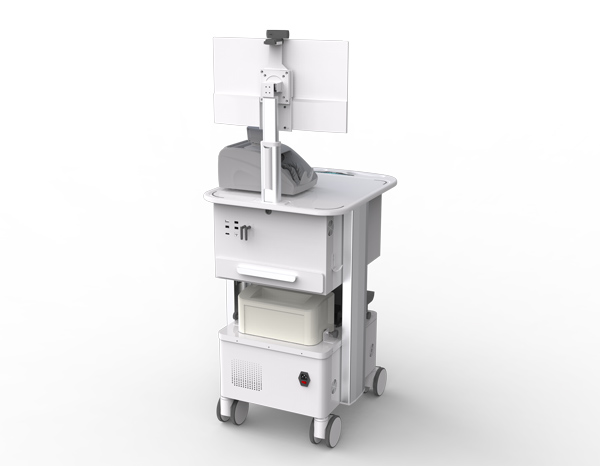

Ultrasound Machines

MY sheet metal aims to provide a positive user experience to the final customers. Creating high-quality enclosures can help achieve this when it comes to electronic components. We keep good control of materials and thickness for the ultrasound machines.

Medical Imaging Equipment

Spectrometry scan equipment, CT scan machines, and PET scan machines rely on sheet metal fabrication to maintain their efficiency and accuracy while meeting strict statistical process control specifications. We provide sheet metal finishing solutions to make your product perfect.

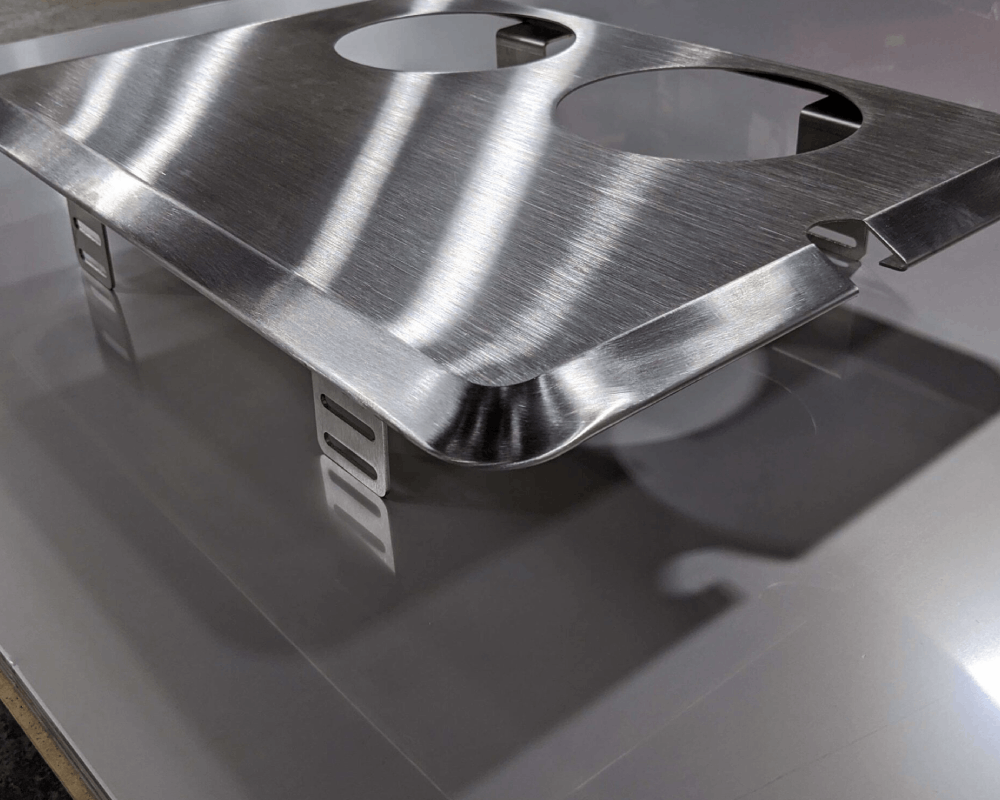

Ablation System

Stainless steel fabrication delivers the high precision essential to create ablation systems and the perfect fit to this kind of devices. MY has capability of using stainless steel 316 with a nice polished surface for you in the sterile environment.

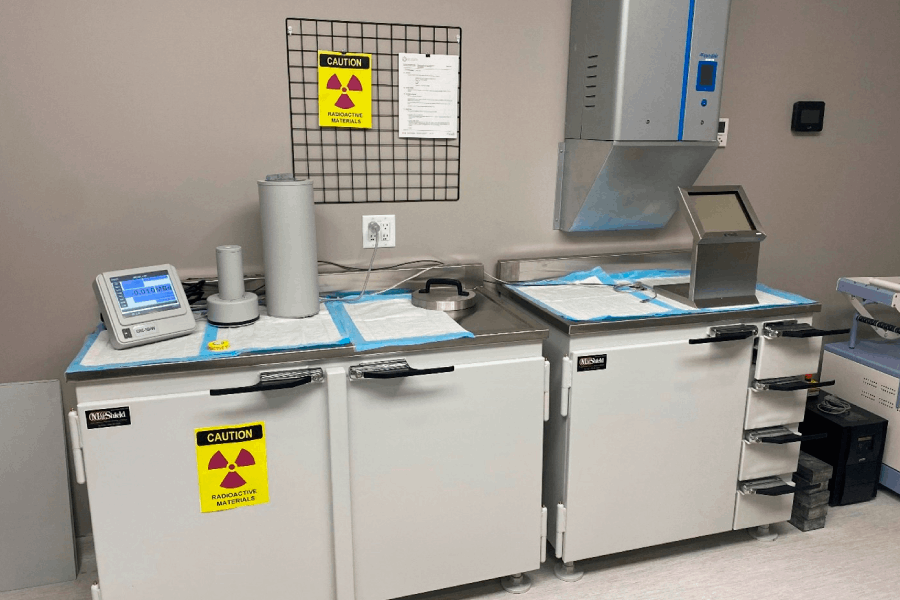

Nuclear Medicine Cabinets

MY sheet metal kept strict control in the whole manufacturing workflow, kept the bend radius consistent for the medicine cabinet. To prevent fractures and substance circulation issues, we carefully keep the bend radius corresponding with the product width.

Common Material Used in Medical Devices

- Stainless Steel. Stainless steel alloy contains chromium and nickel. It is suitable for sheet metal enclosure designs for high-impact applications. You will find a stainless steel component striking with a grained finish.

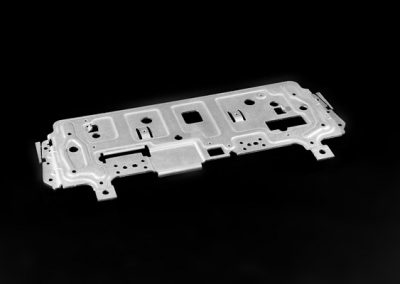

- Aluminum. This metal is lightweight and corrosion-resistant. We suggest 5052 aluminum and 6061 aluminum for medical sheet metal process. 5052 aluminum has incredible bending abilities, even to tight radii without cracking. You can also easily machine and weld this alloy, making it suitable for sheet metal enclosures.